Hey everyone!

I decided that I wanted to make a bikepacking specific tarptent, and have been taking photos along the way in case everything worked out so I could share my method with you guys. Well, everything worked out, so here I am.

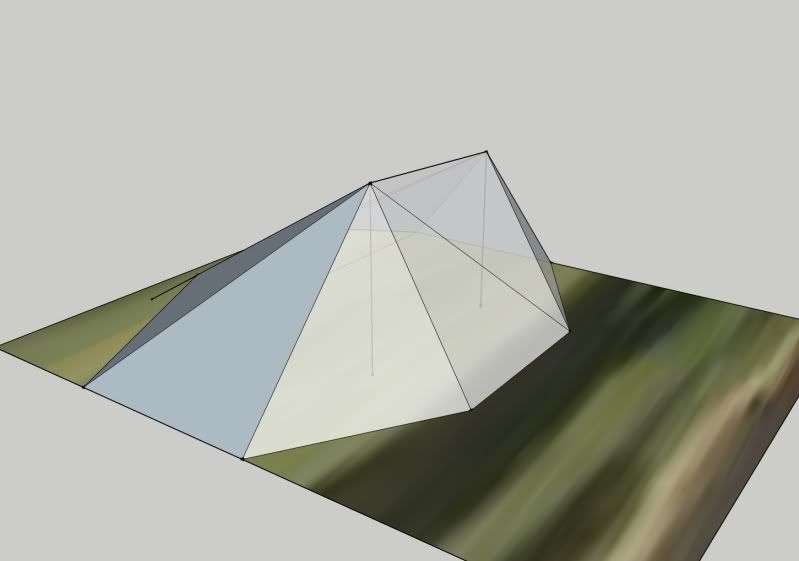

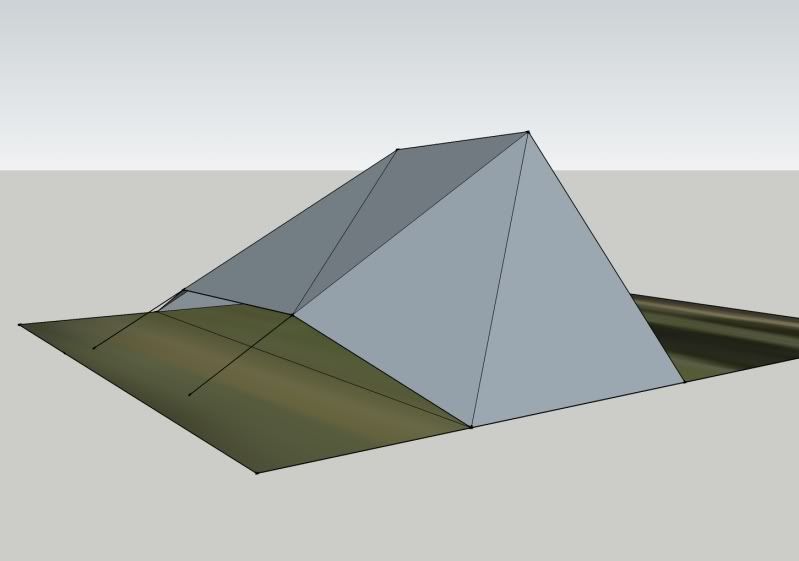

First off, I don't know if the way I did it was the best way, or even a good way, but it seems to have worked. Where I started was Google Sketchup. I got the idea out of my head and into a graphic. Here are a front and back view of the concept:

The supports for the tarp is the bike itself. The two vertical lines you see in the front view are the heights of the apex of my wheels when the bike is turned upside down. I figured that this setup would give me a lot of room with minimal setup. The rear image shows the back side of the tent lifted off the ground for ventilation. Ultimately my plan is to add a bug net insert with a silnylon floor.

The Process:

So here's how it went down. I had a bunch of old $1 fabric from Walmart to use as my template material. The whole purpose of the build I'm describing in this post is to create a template or pattern that I can transfer onto the actual fabric that I'll be using for the final product. When I'm finished with this build, I'll take everything apart so I can trace the flat panels onto the actual fabric. This free's me up to do whatever I want with this fabric. If you look closely you'll see that I have written all over the tent, making notes to myself, or drawing diagrams and recording measurements:

As I went through this whole thing, I always had a sharpie in my pocket, and it was immensely helpful.

So, Step 1: I took my $1 nylon and draped it over the bike, just like the back panel would be in the picture. Then I took my sharpie and marked out places where I thought I might need tieouts. Then I went back to the sewing machine and threw in a bunch of loops of webbing so I could start experimenting with "pitch-points".

Then I went back to the bike draped it again, and staked it down to the ground:

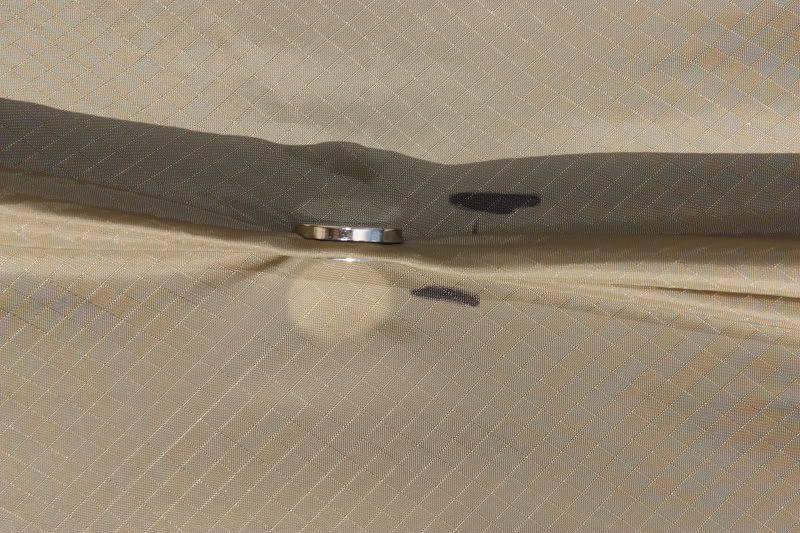

The next step was to figure out how to shape the side panels. If you notice in the Google images above, the side panels are made of two triangles, which is a necessary geometrical feature in order to keep the material from sagging. So to discover the shapes of those triangles I went to the sides of the tarp and gathered the excess fabric, and "pinned" the panels together with magnets (in hindsight, I really should have just used pins to hide the excess fabric). Then I drew lines on each side of the newly forming triangles representing where the two panels should meet:

Gathering the excess (saggy) material:

Drawing lines representing where the two panels should come together:

This next bit was interesting, and I'm not sure how correct it was. I took the whole tarp down and laid out the fabric to connect the lines I made on the side panels. The picture below shows the final result. The lines I made ended up making a curve on both sides, which I tried to make as symmetrical as possible:

I then cut on one of the lines and sewed the cutout panel to the other one, on the opposite line. Then I went back out and re-pitched the tarp:

I think the wrinkles are from failures in symmetry. A step that I might add is to line up both curves, one on top of the other, and make them match perfectly...I think I moved a little too quickly through this step.

Note: For a summer, or warm weather tarp, you could be done right here. Maybe add some kind of a beak to the front if you think you'll get shifting rain in the night, but all in all this isn't a bad tarp setup as is.So, with the back side done, it was time to move onto the front. I took some measurements and ended up cutting a 45"X45" square and pinned it to the front middle panel to pitch it:

Then, the last step was to measure out the front/side triangles. One side was 45", the other side was the length of the front edge between the tire and the ground, and the other side was the length between the square piece and the front outside corner. With those measurements in hand, and now having run out of fabric, I went to a new piece of fabric and cut out the triangles:

All those wrinkles in the fabric above made for a sloppy bit of measuring. Make sure that your fabric is nice and flat before marking out your lines!

Then I sewed the triangle panels onto the front and re-pitched the tarp one last time:

As you can see from the above picture the back right corner is a lot farther out than it needs to be. In the final version I will cut that down to remove the excess fabric.

Here's a shot from the inside:

All in all I'm really happy with the dimensions and the overall feel of the thing. I just ordered some 1.1oz silnylon, and I'll be hunting for an adequate zipper to make a good entrance door, and then I'll put the whole thing together.

The final piece to the puzzle will come when I design the bug net insert. My hope is to make something that I can just attach to the inside so I can leave it at home when I know bugs won't be an issue.

I hope this was useful to someone. Feel free to ask questions. I'll try to remember to post up the final product when I get it finished.

Cheers!