Bike components » Actiontec 20 tooth chainring

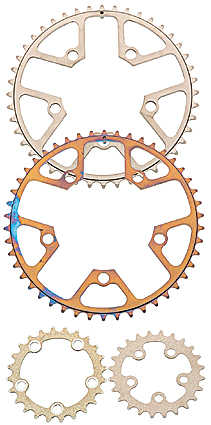

Titanium Chain Rings

Our Chain Rings are CNC laser cut from .115″ thick 8/11 titanium alloy, then CNC machined to .071″ thick at the tooth area, spot faced and hand finished to a brilliant silver nickel finish. They weigh nearly the same as an aluminum CR, but will last 5 times longer. The machined edges stay sharp to ensure quick shifts and promote long chain life. Weight: 18 gr – 96 gr.

Available in 20 tooth, even for 4 bolt 64mm BCD cranks (e.g. any Shimano crank in the last ~4 years)

Product website: http://www.actiontec.us/ti&steel.htm

Please rate this product: (no login required)

November 16th, 2008 in

Bike components

(16 votes, average: 3.56 out of 5)

(16 votes, average: 3.56 out of 5)

This looks tempting for my 29er. They have 3 options: a heat treated titanium for $75, a regular titanium for $45, and a stainless steal for $7.50…$7.50 sounds pretty good. Anyone have any info on the differance other than price?

I have the regular titanium version, in 20 tooth 4 bolt. The advantage of the ti version is, as Russ at actiontec told me on the phone, “it’ll outlast your bike.” That’s turned out to be true — I’ve had mine for about 4 years now, and it still doesn’t show much sign of wear.

$7.50 is a steal [sic] for steel, though. That’s in the 4 bolt pattern? I might find that hard to pass up — little rings do last a long time anyway.

On the most recent crankset (’08 XT) I had to dremel down the crank a bit to prevent the chain from contacting the crank. It was unusable until I did this (chain falling of). But it didn’t take much grinding to allow the chain to sink fully into the teeth.

I live in Whistler… the 20 tooth ring , is a great bail out gear … and it is very durable. In fact it is going on my new bike for this year…..

LP, do you have the titanium or stainless ring?

i got the TI version and had quite a hard time spacing it just right to get shifting to work. then i found out that some of the teeth were not cut right. had to send it back twice and finally got one that was cut correctly.

since then i switched back to a XTR 22t, just don’t need it on my 29er even loaded up

Just bumped into this awesome website and I have used an Actiontec ti 20t for many chains since 2005. This product works and is worth it if you want/need lower gears. I use a 34t cassette with it. The downside was installation where I needed to file down one of the chainring bolt heads on the side. What I did was torque everything down, observe and mark the one bolt side that contacted the chain, take it all apart, and then file the bolt down enough, and reassemble. Had to do it twice because it snugged down further. This was a PITA, but it has been worth it. Using M960 XTR cranks and did not have to file any of the crank. Aluminum crank would be easy to file. The steel bolt was difficult, and neccesary no matter what. I would not use aluminum chainring bolts, especially on the granny gear.

Did the same thing with my XTR crank bolts, worked like a charm but I had to remove material from the heads of all the bolts. To make this easy I suggest using a Dremel tool. That worked fast and allowed precision shaping

The lower gearing combo of 20/34F/R made many hills climbable in northen Georgia and Tennessee. I can’t see a down side to this for me. I am running 26×2.25 tires on an old Litespeed Ocoee set up for trekking.

bill

the only problem is whether or not you agree to grind some materials at the spiders.

Does the 20 tooth chainring work on a 3×9 deraieur system, as I have a touring bike

Is it compatible for a 3×9 derailleur touring set up

I run a 20–34–48 chain rings matched to a 11–36 10 speed cassette with Sram derailleurs and shifters……this gives me super low for climbs and super high for smooth decents….yes I had to grind the crank arm to get the chain to seat properly with the 20 tooth…….the other modification was to grind the outer front derailleur cage. to accommodate the 48 tooth the derailleur needs to be high on the seat tube….to not have the chain drag in the bottom of the cage in the 20 tooth the derailleur needs to ride low on the seat tube…..Grind the outer plate of the front derailleur and get the best of both….TIP….Derailleur steel is pretty tough and the amount that needs to be ground off is substantial ( matching the arc of the 48 tooth) ….so…. use a full on angle grinder with metal cutoff wheel…not a Dremel, too wimpy…Ummmmm …skill is required